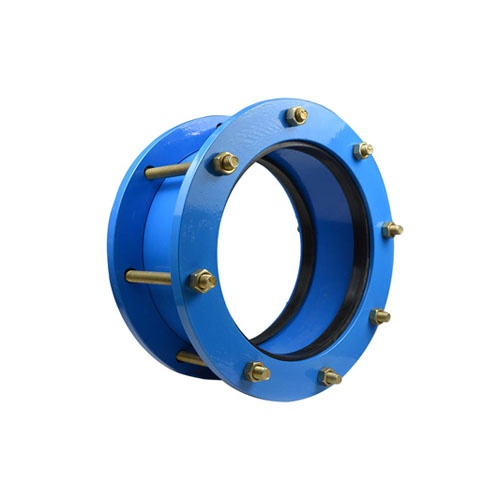

SSJB Metal Expansion Joint

Description

This metal expansion joint is designed to provide flexibility and vibration absorption in piping systems. Its rugged construction makes it ideal for use in industrial, commercial, and residential applications. It features a strong stainless steel bellows that can be adjusted to accommodate different pipe sizes and shapes. The joints are also fully sealed so they can withstand high temperatures and pressures without leaking or suffering from corrosion. This product is available in several sizes and configurations to meet the needs of any project requirements.

SSJB Metal Expansion Joint, also called flexible coupling, flexible pipe coupling, slip on coupling, mechanical coupling, dresser coupling, type 38 coupling and others. Mechanical pipe coupling is made up of follower, sleeve, rubber seals and other components. This type coupling’s function is similar with rigid coupling, connecting two pipes, without welding or flange, only screw the bolts and nuts, the rubber seals will prevent leakages.

| Nominal diameter | External diameter | External dimension | N – Th. | |||

| Length | D | 0.25 – 1.6Mpa | 2.5 – 64Mpa | |||

| L | L | |||||

| 65 | 76 | 180 | 208 | 155 | 4 – M12 | 4 – M12 |

| 80 | 89 | 165 | ||||

| 100 | 108 | 195 | ||||

| 100 | 114 | 195 | ||||

| 125 | 133 | 225 | ||||

| 125 | 140 | 225 | 4 – M16 | |||

| 150 | 159 | 220 | 255 | 4 – M16 | 6 – M16 | |

| 150 | 168 | 255 | ||||

| 200 | 219 | 310 | ||||

| 225 | 245 | 335 | ||||

| 250 | 273 | 223 | 375 | 6 – M20 | 8 – M20 | |

| 300 | 325 | 220 | 273 | 440 | 10 – M20 | |

| 350 | 355 | 490 | 8 – M20 | |||

| 350 | 377 | 490 | ||||

| 400 | 406 | 540 | ||||

| 400 | 426 | 540 | ||||

| 450 | 457 | 590 | 10 – M20 | 12 – M20 | ||

| 450 | 480 | 590 | ||||

| 500 | 508 | 645 | ||||

| 500 | 530 | 645 | ||||

| 600 | 610 | 750 | ||||

| 600 | 630 | 750 | ||||

| 700 | 720 | 855 | 12 – M20 | 14 – M20 | ||

| 800 | 820 | 290 | 355 | 970 | 12 – M24 | 16 – M24 |

| 900 | 920 | 1070 | 14 – M24 | 18 – M24 | ||

| 1000 | 1020 | 1170 | 14 – M24 | 18 – M24 | ||

| 1200 | 1220 | 1365 | 16 – M24 | 20 – M24 | ||

| 1400 | 1420 | 377 | 1590 | 18 – M27 | 24 – M27 | |

| 1500 | 1520 | 1690 | 18 – M27 | 24 – M27 | ||

| 1600 | 1620 | 1795 | 20 – M27 | 28 – M27 | ||

| 1800 | 1820 | 2000 | 22 – M27 | 30 – M30 | ||

| 2000 | 2020 | 2200 | 24 – M27 | 32 – M30 | ||

| 2200 | 2220 | 400 | 2420 | 26 – M30 | ||

| 2400 | 2420 | 2635 | 28 – M30 | |||

| 2600 | 2620 | 400 | 2835 | 30 – M30 | ||

| 2800 | 2820 | 3040 | 32 – M33 | |||

| 3000 | 3020 | 3240 | 34 – M33 | |||

| 3200 | 3220 | 3440 | 36 – M33 | |||

| 3400 | 3420 | 490 | 3640 | 38 – M33 | ||

| 3600 | 3620 | 3860 | 40 – M33 | |||

| 3800 | 3820 | 500 | 4080 | 40 – M36 | ||

| 4000 | 4020 | 4300 | 42 – M36 | |||

| No. | Name | Quantity | Material |

| 1 | Cover | 2 | QT400 – 15、Q235A、ZG230 – 450、1Cr13、20 |

| 2 | Sleeve | 1 | Q235A、20、16Mn、1Cr18Ni9Ti |

| 3 | Gasket | 2 | NBR、CR、EPDM、NR |

| 4 | Bolt | n | Q235A、35、1Cr18Ni9Ti |

| 5 | Nut | n | Q235A、20、1Cr18Ni9Ti |

Advantage

It provides superior performance compared to standard rubber or plastic components due to its durability as well as its ability to resist wear caused by pressure surges over time. Additionally, this product has excellent resistance against water infiltration which helps protect the integrity of your pipes over extended periods of time while still providing ample flexibility for installation purposes.