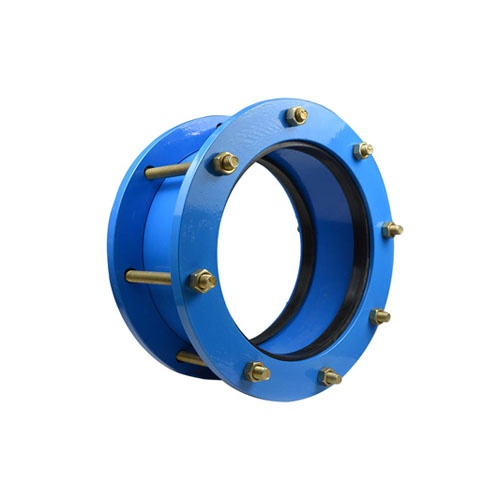

I-SSJB Metal Expansion Joint

Incazelo

Lesi sixhumanisi sokunwetshwa kwensimbi siklanyelwe ukuhlinzeka ngokuguquguquka nokumuncwa kokudlidliza ezinhlelweni zamapayipi.Ukwakhiwa kwayo okumazombezombe kuyenza ilungele ukusetshenziswa ezimbonini, ezentengiselwano, nasezindaweni zokuhlala.Ifaka imibhobho yensimbi engagqwali eqinile engalungiswa ukuze ivumelane nosayizi namapayipi ahlukene.Amalunga nawo avalwe ngokugcwele ukuze akwazi ukumelana namazinga okushisa aphezulu kanye nezingcindezi ngaphandle kokuvuza noma ukugqwala.Lo mkhiqizo utholakala ngosayizi abambalwa kanye nokucushwa ukuze uhlangabezane nezidingo zanoma yiziphi izimfuneko zephrojekthi.

I-SSJB Metal Expansion Joint, ebizwa nangokuthi i-flexible coupling, ukuhlanganisa ipayipi okuguquguqukayo, ukushelela ekuxhumaneni, ukuhlanganisa ngomshini, ukuhlanganisa i-dresser, uhlobo lwe-38 coupling nokunye.Ukuhlanganisa ipayipi lomshini kwenziwa umlandeli, umkhono, izimpawu zenjoloba nezinye izingxenye.Umsebenzi walolu hlobo lokuhlanganisa ufana nokuhlanganisa okuqinile, ukuxhuma amapayipi amabili, ngaphandle kwe-welding noma i-flange, kuphela isikulufa ama-bolts namantongomane, izimpawu zenjoloba zizovimbela ukuvuza.

| Ububanzi bokuzisholo | Ububanzi bangaphandle | Ubukhulu bangaphandle | N - Th. | |||

| Ubude | D | 0.25 - 1.6Mpa | 2.5 - 64Mpa | |||

| L | L | |||||

| 65 | 76 | 180 | 208 | 155 | 4 – M12 | 4 – M12 |

| 80 | 89 | 165 | ||||

| 100 | 108 | 195 | ||||

| 100 | 114 | 195 | ||||

| 125 | 133 | 225 | ||||

| 125 | 140 | 225 | 4 – M16 | |||

| 150 | 159 | 220 | 255 | 4 – M16 | 6 – M16 | |

| 150 | 168 | 255 | ||||

| 200 | 219 | 310 | ||||

| 225 | 245 | 335 | ||||

| 250 | 273 | 223 | 375 | 6 – M20 | 8 – M20 | |

| 300 | 325 | 220 | 273 | 440 | 10 – M20 | |

| 350 | 355 | 490 | 8 – M20 | |||

| 350 | 377 | 490 | ||||

| 400 | 406 | 540 | ||||

| 400 | 426 | 540 | ||||

| 450 | 457 | 590 | 10 – M20 | 12 – M20 | ||

| 450 | 480 | 590 | ||||

| 500 | 508 | 645 | ||||

| 500 | 530 | 645 | ||||

| 600 | 610 | 750 | ||||

| 600 | 630 | 750 | ||||

| 700 | 720 | 855 | 12 – M20 | 14 – M20 | ||

| 800 | 820 | 290 | 355 | 970 | 12 – M24 | 16 – M24 |

| 900 | 920 | 1070 | 14 – M24 | 18 – M24 | ||

| 1000 | 1020 | 1170 | 14 – M24 | 18 – M24 | ||

| 1200 | 1220 | 1365 | 16 – M24 | 20 – M24 | ||

| 1400 | 1420 | 377 | 1590 | 18 – M27 | 24 – M27 | |

| 1500 | 1520 | 1690 | 18 – M27 | 24 – M27 | ||

| 1600 | 1620 | 1795 | 20 – M27 | 28 – M27 | ||

| 1800 | 1820 | 2000 | 22 – M27 | 30 – M30 | ||

| 2000 | 2020 | 2200 | 24 – M27 | 32 – M30 | ||

| 2200 | 2220 | 400 | 2420 | 26 – M30 | ||

| 2400 | 2420 | 2635 | 28 – M30 | |||

| 2600 | 2620 | 400 | 2835 | 30 – M30 | ||

| 2800 | 2820 | 3040 | 32 – M33 | |||

| 3000 | 3020 | 3240 | 34 – M33 | |||

| 3200 | 3220 | 3440 | 36 – M33 | |||

| 3400 | 3420 | 490 | 3640 | 38 – M33 | ||

| 3600 | 3620 | 3860 | 40 – M33 | |||

| 3800 | 3820 | 500 | 4080 | 40 – M36 | ||

| 4000 | 4020 | 4300 | 42 – M36 | |||

| Cha. | Igama | Ubuningi | Okubalulekile |

| 1 | Ikhava | 2 | QT400 – 15, Q235A, ZG230 – 450, 1Cr13,20 |

| 2 | Umkhono | 1 | I-Q235A, 20, 16Mn, 1Cr18Ni9Ti |

| 3 | I-Gasket | 2 | I-NBR, CR, EPDM, NR |

| 4 | Ibholidi | n | Q235A, 35,1Cr18Ni9Ti |

| 5 | Nut | n | Q235A, 20,1Cr18Ni9Ti |

Inzuzo

Inikeza ukusebenza okuphezulu kakhulu uma kuqhathaniswa nerabha evamile noma izingxenye zepulasitiki ngenxa yokuqina kwayo kanye nekhono layo lokumelana nokuguga okubangelwa ukunyuka kwengcindezi ngokuhamba kwesikhathi.Ukwengeza, lo mkhiqizo unokumelana okuhle kakhulu nokungenwa kwamanzi okusiza ukuvikela ubuqotho bamapayipi akho isikhathi eside ngenkathi usanikeza ukuguquguquka okwanele ngezinjongo zokufakwa.